A field trial of 3D Printing to assess its potential for improving the effectiveness and efficiency of the humanitarian response

Project overview

3D printing has the potential to improve the efficiency and effectiveness of the humanitarian logistic response by reducing lead times, avoiding nugatory ‘just in case’ transport and warehousing, and using postponement techniques to manufacture locally to meet an identified need. The aim of the proposed field research is to test and validate the above theoretical benefits and associated training/education requirements in a variety of field settings, and to identify any unanticipated benefits and challenges.

Project solution

This project offers [specific solution or intervention] to tackle [challenge]. By implementing [strategies, tools, or innovations], the project aims to achieve [desired outcomes]. The approach is designed to [specific actions or methods] to bring about meaningful change in [community, region, or issue area].

Expected outcomes

This project aims to achieve [specific outcomes], such as [measurable results, improvements, or changes]. The expected impact includes [benefits to the target community, advancements in research or innovation, or long-term effects]. By the end of the project, we anticipate [specific changes or milestones] that will contribute to [broader goals or objectives].

WHAT IS THE HUMANITARIAN NEED?

Against the background of a global rise in the number of people affected by disasters/complex emergencies, it has been estimated that 60-80% of the income of aid agencies is spent on logistics[1] (defined as the procurement, transport, warehousing and distribution of food, water, materials and equipment, etc).

WHAT IS THE INNOVATIVE SOLUTION?

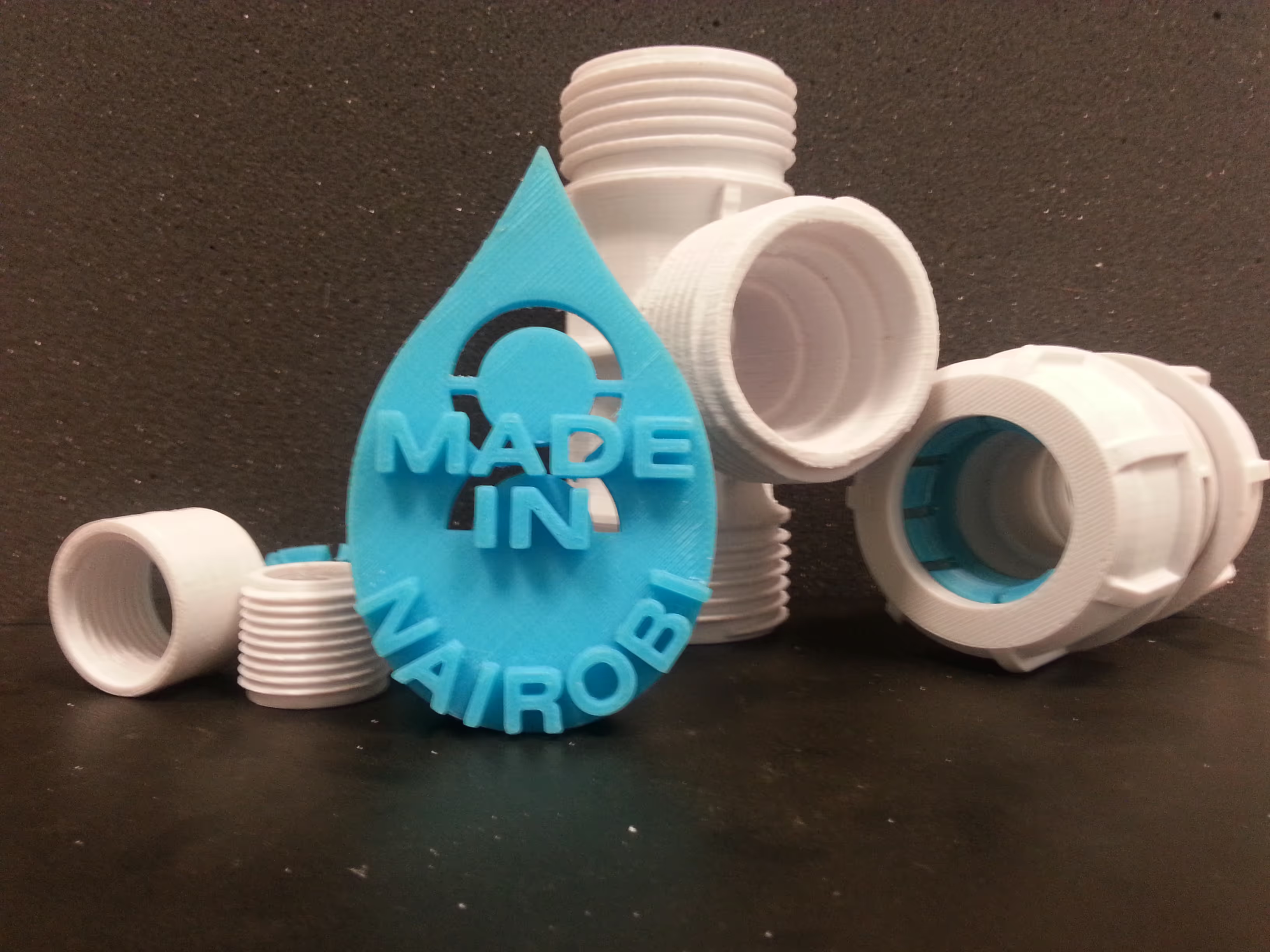

3D printing has the potential to improve the efficiency and effectiveness of the humanitarian logistic (HL) response by reducing lead times, avoiding nugatory ‘just in case’ transport and warehousing, and using postponement techniques to manufacture locally to meet an identified need.

This innovation is aimed at improving the effectiveness and efficiency of the logistic processes by:

- Avoidance of the transport and warehousing of items that are not subsequently required.

- Local manufacture of items to meet an identified need thereby avoiding procurement and transport delays.

- Use of a single source material that does not require special packaging and/or handling, has a high mass:volume ratio, and from which multiple items can be produced.

- Production of bespoke items that are not readily available as spare parts.

- Introduction of operational benefits (such as in line filtration) which cannot easily be created using mass production (injection moulding) techniques.

Thus, while 3D printing is not an innovation of itself, this technology has yet to be used in a humanitarian programme setting.

WHAT ARE THE EXPECTED OUTCOMES?

The results will be disseminated:

- Within the Humanitarian Logistics community at large via the Humanitarian Logistics Association (HLA) which is the professional body for humanitarian logisticians.

- Within the academic community via a refereed journal article in an appropriate publication such as the Journal of Humanitarian Logistics and Supply Chain Management.

- Through the internal mechanisms of the host organisation (Oxfam GB).

- By feedback to the equipment manufacturers with the aim of developing a set of 3D printers which are optimised for field operations.

NB. This project is being carried out simultaneously with the ‘Making humanitarian supplies in the field‘ HIF-funded project by Field Ready. Where possible the two projects will share results and learning to greater inform the evidence surrounding the use of 3D printing in humanitarian crises.

[1] Tatham, P.H., and Pettit, S.J. (2010), “Transforming humanitarian logistics: the journey to supply network management”, International Journal of Physical Distribution and Logistics Management, Vol. 40 No. 8/9, pp. 609-622.

Read the project's findings

Read the 'Three dimensional printing – a key tool for the humanitarian logistician?' article published in the Journal of Humanitarian Logistics and Supply Chain Management.

[.cta_link]Read now[.cta_link]

Project delivery & updates

Stay up to date with the latest developments from this project. Here, you will find details on what has been delivered, resources created, and regular updates as the project progresses. Access key documents, reports, and other materials to see how the project is making an impact.